Sistema di Isolamento per Test Analitici

Progettato per le industrie farmaceutiche

Il Sistema di Isolamento per Test Analitici è stato progettato per le industrie farmaceutiche che richiedono i più alti livelli di contenimento durante la manipolazione di sostanze potenzialmente pericolose (HAPIs).

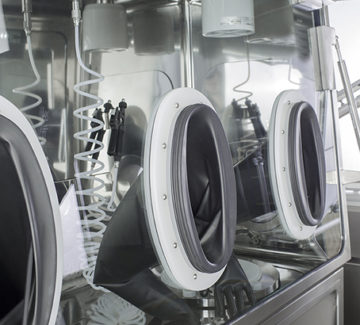

Questo sistema di isolamento è un dispositivo di contenimento GMP di Classe II ed è composto da una camera di lavoro a 4 guanti e da un airlock di ingresso/uscita.

All’interno dell’isolatore sono integrati una RTP (modello DPTE® 270-XS) ed un sistema a sacco continuo. L’isolatore è inoltre equipaggiato con un sistema Wash-In-Place (WIP) per le operazioni di lavaggio manuali.